| Here is my first attempt at sumping the tank. I cut a hole in the front bottom of the tank.

My original ideal was to use a baking loaf pan. After trying to weld the pan, I realized that the gauge

of the steel was too thin and would not work. |

|

|

|

|

|

|

| After the loaf pan failure, I decided to make my own sump out of 18 gauge steel. I made

the sump out of a single piece of steel and bent up the sides and just had to weld up

the corners. After I welded up the box, I put water in the box to test whether it

was watertight and would not leak. |

|

|

|

|

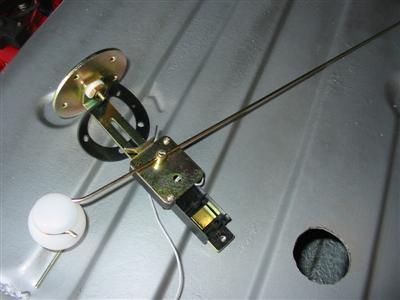

| I then cut up the donor pump assembly to remove the tubes I do not need and to set the

pump to the proper depth. Originally, I modified and welded the 3rd gen sending unit

to work with my setup. Unfortunately, the welding seemed to mess up the sending

unit and it no longer functioned properly. |

|

|

|

|

|

|

|

|

| The next step was to weld in the sump. I added holes to the top of the sump to allow fuel

to enter the sump. |

|

|

|

|

|

|

| I also removed the existing tank vents for emissions and welded up the holes

shut. I will be running a vented gas cap to allow the tank to vent. |

|

|

| The next step was to strip the exterior of the tank. Prior to this I cleaned up the

interior of the tank. I was able to wire wheel the interior of the tank using the hole for

the sump before it was welded in. I then treated and sealed the interior using the POR-15

fuel tank products. |

|

|

| I then used Rustoleum Hammered Silver paint to coat the exterior of the tank. |

|

|

|

|

|

|

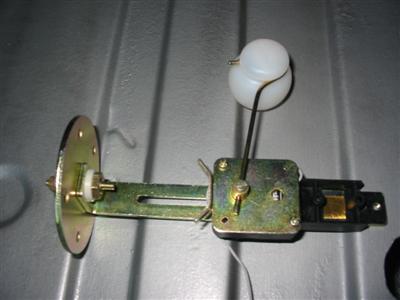

| After some research, I decided to use a VDO universal sending unit. This required me to

cut another hole in the top of the tank. I then fed the ground and sender lines to the

original fuel pump assembly. |

|

|

|

|

|

|

|

|

| When I took the pump assembly from the 3rd gen Camaro, I also took all the wiring with it.

This included the plug that was mounted to the floor. I decided to mount the plug in the

area where the emmisions vent was mounted behind the back seat. I had to mount it to

a plate that covered the larger original hole. |

|

|

|

|

|

|

| Next I installed a return feed using a bulkhead connector and a piece of 1/2 inch aluminum

line. |

|

|

|

|

|

|

| I then flared the 3/8 inch line with a 37 degree flare tool and installed an AN-6 tube nut

coupler and sleeve fitting. |

|

|

|

|

| Here is everything installed in the tank. |

|

|

| I stripped and then coated the Fuel Tank straps with POR-15. I later coated the straps

with gloss black paint. |

|

|

| Here is the tank installed. |

|

|