| Here is the regulator installed on the front right framerail. NHRA rules requires the

regulator to be installed 6 inches forward or aft of the firewall/bellhousing. This

picture is from before the engine was installed. |

|

|

|

|

| Here is the Russell aluminum fuel line. The line is 1/2 red anodized aluminum fuel line and

that comes in a 25 foot roll. |

|

|

| Here are all the Summit black -08AN fittings, black Summit Racing Braided Nylon hose and

the Trick Flow TFX 10 Micron Inline Fuel Filter. |

|

|

|

|

|

|

| Here is one of the completed braided lines. Building the nylon lines using the Summit hose

ends was easy to do. I would wrap the line with tape and cut the line using a cut off

wheel. I then assembled the line using a vise and an adjustable wrench. I wrapped the

fittings with tape to avoid scratching the surfaces. The only other additional step

was to use a little oil in the hose to lube the fitting during installation. |

Here is a sample of the flares made on the aluminum lines. The AN fittings require a 37 degree

single flare. The flares use a tube nut to connect to the fitting and a tube sleeve to support the

flare in the fitting. |

|

|

| The Trick Flow filter is mounted in the rear of the car right after the pump. I used

conduit brackets and some rubber strips to mount the filter under the trunk. |

|

|

|

|

| I ran the hard line by following the frame rails and subframe connectors. I used insulated

1/2 clamps to mount the line to the car. The line is on the outside front frame rail and

moves to the inside at the end of the front frame rail. NHRA rules requires hard lines to

be protected like this. |

|

|

|

|

|

|

|

|

|

|

| Here is the carb dual feed fuel line. It has a -08 fitting on one side and a fuel pressure

gauge on the other side. |

|

|

| Here is the stock throttle cable and aftermarket bracket that I originally had on the engine. As

you can see, the additional height of the Holley manifold put the cable at a bad angle. This would

only be worse with a spacer installed. |

I was able to pick up this Holley billet throttle bracket up cheap. |

|

|

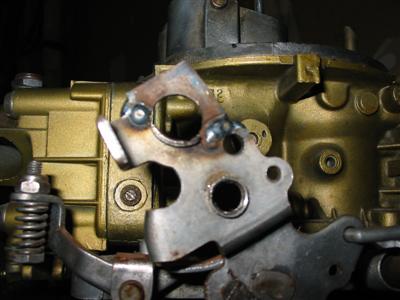

| After mounting the bracket, I noticed that someone had cut the carburetor mounting arm

at some time. They cut the top half off that included the hole that the return spring

bracket was to mount to. I welded some steel to the top of the throttle arm and

drilled a hole in in so I could mount the return spring bracket. |

|

|

|

|

| I also picked up a 1 inch carb spacer and installed it to gain additional carb clearance to

the manifold and gain some top end power. |

|

|

| Here is the carb installed on top of the spacer. This combination pushed the limits of

the factory throttle cable. I decided to replace the throttle cable with a Spectre Universal

Throttle Cable. |

|

|

|

|

| Here is the feed line from the regulator to the carburetor. I used -08 braided hose for

the line. |

|

|

|

|

| Here is the completed fuel system with a 14 inch diameter Cal Custom Chrome drop base air

cleaner with a 3 inch high filter. This complete setup still has a few inches of clearance

with my cowl induction hood. Some day I will add a 4 or 5 inch tall filter.

|

|

|